Crimping

Sheet metal crimping is an essential technique in the field of metallurgy, which allows metal elements to be assembled and fixed in a precise and durable manner.

This method is widely used in the manufacturing of parts for various sectors, including electronics, aerospace and defense.

Precise and Reliable Know-How

Crimping is an essential technique for making strong and durable assemblies.

This method involves mechanically deforming a part to hold or assemble components, providing a reliable alternative to welding.

Advanced Crimping Techniques

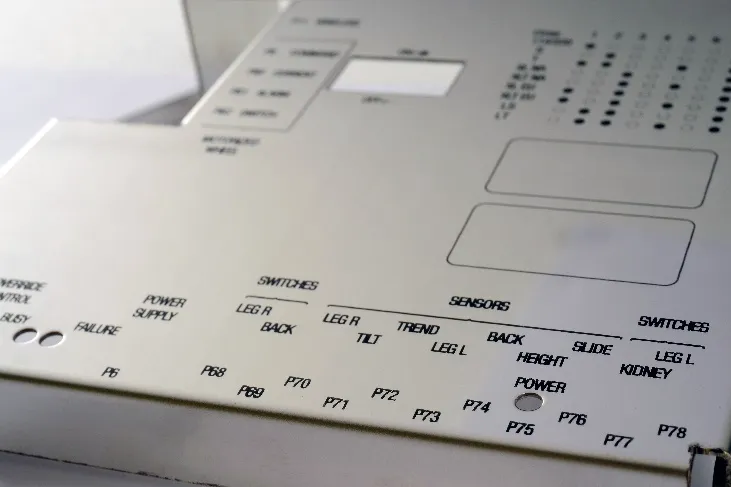

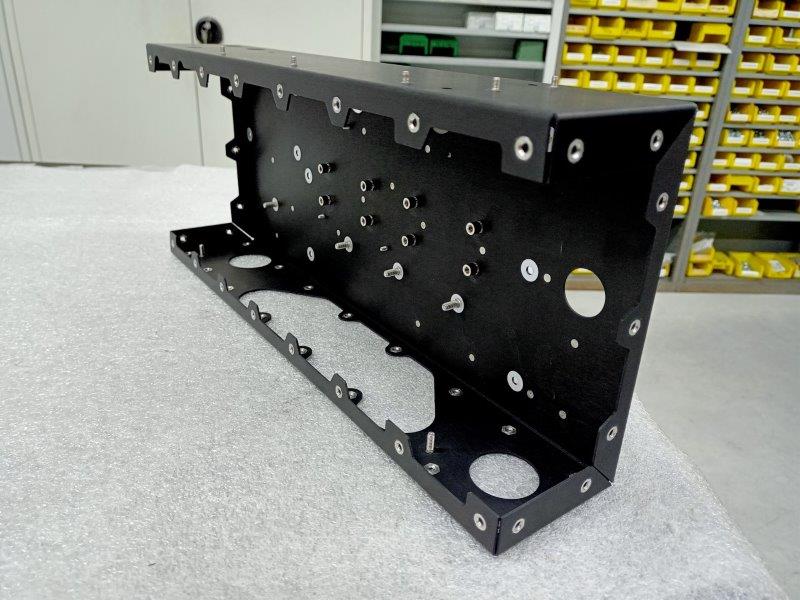

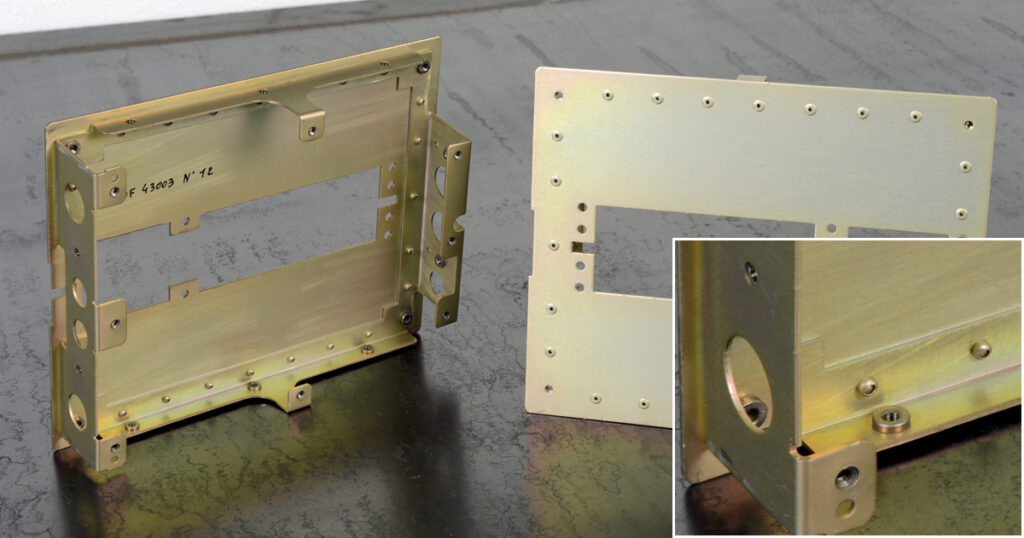

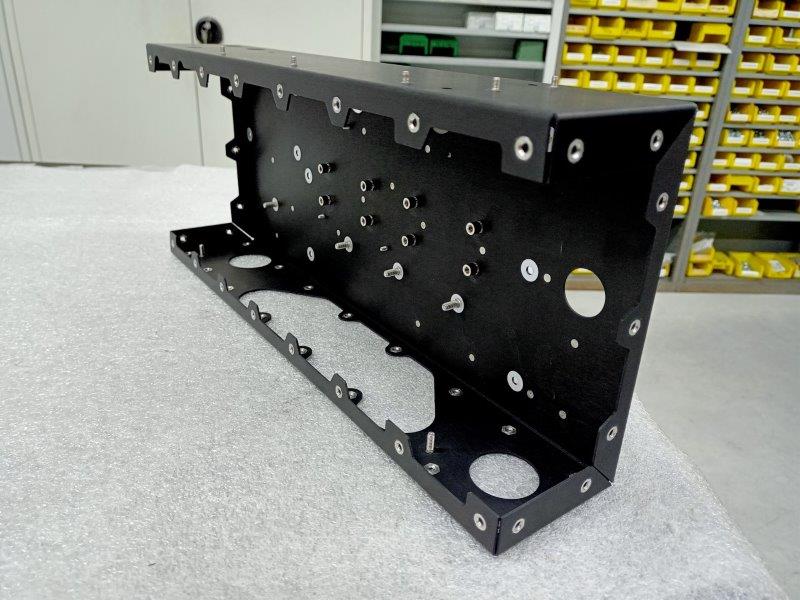

We use modern equipment, such as crimping presses suitable for various types of materials, including metals and plastics.

Thanks to our know-how, we can create precise assemblies that guarantee the strength and durability of finished products.

Each crimping operation is carried out with careful attention to detail, ensuring results that meet the highest standards.

Optimization & industrialization

We also support you in the optimization and industrialization of your products. Thanks to our expertise in fine sheet metal work, we optimize the costs, deadlines and quality of your productions.

We master every step of the process, from raw material sourcing to final assembly, including laser cutting, bending, welding and crimping.

Project monitoring

Tolanjou attaches great importance to project monitoring. We ensure transparent and regular communication with our clients throughout the development process.

Our objective is to guarantee that each project is carried out in the best conditions, respecting the deadlines and budgets set.

ADVANTAGES

of CRIMPING

Crimping creates strong, durable mechanical connections, ensuring excellent resistance to vibration and shock.

Crimping provides high precision, ensuring consistent, high-quality connections, essential for demanding applications.

Crimping produces clean, unobtrusive connections, improving the final appearance of products.

By eliminating the need for solders or adhesives, crimping reduces production and material costs, while minimizing the risk of defects.

Diversified applications

Our crimping service meets the needs of many industrial sectors, such as:

Each application benefits from our expertise and commitment to providing high-quality assemblies that meet the most demanding specifications.

Quality commitment

Quality is at the heart of our approach. We are committed to providing products that meet the highest standards, ensuring durability and customer satisfaction. Our manufacturing processes include rigorous controls at each stage to ensure results that meet expectations.

We are ready to transform your ideas into concrete and sustainable solutions.

To discover our achievements and learn more about our expertise.

Our others know-how

Contact us today